ROBOTEK

OOO

Overview

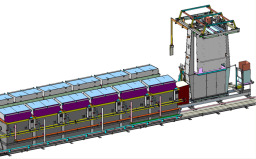

Research and Development enterprise ROBOTEK-NN, Nizhny Novgorod, the Russian Federation, has been specializing in mechanical engineering from 2001. The enterprise has developed an innovative technology for metal working and now offers European manufacturing firms robotic galvanic lines (RGL).

RGL is a universal and at the same time the most efficient solution for all types of electroplating industry –for both mass and small-scale production.

Competitive advantages:

1. Developer ROBOTEK-NN has extensive experience of metalworking. The owner and head of the company is Candidate of Technical Sciences. He defended the dissertation on this subject and is the main developer of the innovative technology.

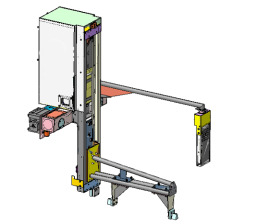

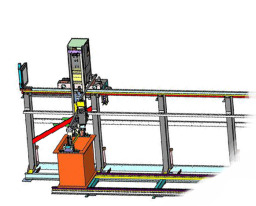

2. Operation of flexible automation: parts of different technical processes are processing in the same production line without preliminary line load planning = technological flexibility and productivity at the same time.

3. Energy efficiency = twofold efficiency increase in comparison with traditional lines.

4. Original ventilation system of RGL provides:

a. chemicals saving due to minimizing of eluates carry-over from the bath surface;

b. minimizing of power inputs for bath heating.

5. Manufacturing areas saving due to double-row floor modular construction of RGL. High productivity of the equipment.

6. Short terms of mounting and adjustment (2-3 weeks) due to construction modularity and highly experiences technical personnel.

7. Minimal maintenance costs, easily understood for amateurs programming, simple and reliable performance.

The companies, interesting for cooperation:

Production company which specializes in engineering and/or instrumentation.

Cooperation type: service delivery and equipment supply.

Cooperation on the basis of the Contract for mounting of robotic galvanic line (RGL) by individual project.

RGL is a universal and at the same time the most efficient solution for all types of electroplating industry –for both mass and small-scale production.

Competitive advantages:

1. Developer ROBOTEK-NN has extensive experience of metalworking. The owner and head of the company is Candidate of Technical Sciences. He defended the dissertation on this subject and is the main developer of the innovative technology.

2. Operation of flexible automation: parts of different technical processes are processing in the same production line without preliminary line load planning = technological flexibility and productivity at the same time.

3. Energy efficiency = twofold efficiency increase in comparison with traditional lines.

4. Original ventilation system of RGL provides:

a. chemicals saving due to minimizing of eluates carry-over from the bath surface;

b. minimizing of power inputs for bath heating.

5. Manufacturing areas saving due to double-row floor modular construction of RGL. High productivity of the equipment.

6. Short terms of mounting and adjustment (2-3 weeks) due to construction modularity and highly experiences technical personnel.

7. Minimal maintenance costs, easily understood for amateurs programming, simple and reliable performance.

The companies, interesting for cooperation:

Production company which specializes in engineering and/or instrumentation.

Cooperation type: service delivery and equipment supply.

Cooperation on the basis of the Contract for mounting of robotic galvanic line (RGL) by individual project.

General information

51-100

€1,000,001-2,500,000

256-256.png)