ROBOTEK

OOO

Electroplating

Robotics Metalloobratoka-

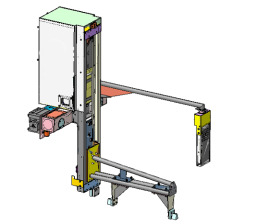

Transport robot with a capacity up to 50 kg

Transport robot with a capacity up to 50 kg, Console type, designed to complete podvesočnyh electroplating lines. Transport robot can be used in lines with depth not more than 1100 mm and of a length not exceeding 1300 mm. specs.- dimensions:-length-700 mm-width without console and remote manual control rods-430 mm-height 1600 mm.

- own Weight-not more than 150 kg

- load capacity 50 kg

- vertical stroke console-1140 mm.

- vertical movement Speed console-200 mm/sec

- Speed horizontal movement-600 mm/sec

- positioning accuracy-± 5 mm.

- number of concurrent suspensions-up to 7 PC.

- number of programmable technology-up to 15;

- number of programmable washing modes-to 7.

- power supply-0.4 kW

- supply voltage-380 v, 50 Hz, 3 phases.

- Connecting cable 10h1, flat 5.

- Profile navigation paths-smooth rake 40 x 40 (mm)

- transport robot requires adaptation to existing navigation routes or manufacturing of new .

- commissioning are carried out only by specialists of «RobotÈk.

-

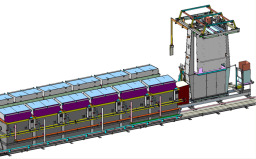

Galvanic line of robotic equipment

Location of baths in the line is determined by the sequence of technological operations and the size of the supplied production areas. The photo shows the robotic line with two location. Possible location of equipment in a multiprocessing robotic line. Frame line is mounted directly on the floor of the shop. To exclude the vibration of running routes and prevent the accumulation of dirt under the bathtub base frame can be podlito concrete. Conclusions from the ventilation ducts are directed upwards or downwards. Stuff shells baths, ventilation systems, pipes-polypropylene. On request can be applied to other materials. The line can be operated by one, two, three or four traffic robots depending on the specified performance. Number of transport robots is determined at the design stage of a business proposal. -

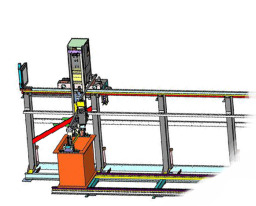

Galvanic line robotic single

Location of baths in the line is determined by the sequence of technological operations and the size of the supplied production areas. Possible location of equipment in a multiprocessing robotic line. Frame line is installed directly on the floor of the shop. To exclude the vibration of running routes and prevent the accumulation of dirt under the bathtub base frame can be filled with concrete. Conclusions from the ventilation ducts are directed upwards or downwards. Stuff shells baths, ventilation systems, pipes-polypropylene. On request can be applied to other materials. The line can be operated by one, two, three or four traffic robots depending on the specified performance. Number of transport robots is determined at the design stage of a business proposal. -

256-256.png)

The onboard controller is the base element of the control system

SRGL-m carries out the operation of the line as polnodostupnoj queueing system. Provides continuous stream mode multiprocessing lines by combining single-threaded processing nondeterministic set details of various technological processes (without prior planning of loading lines in the dynamics of their receipt). SRGL-m provides the following control parameters:-number of technological processes implemented in the line-up to 15; -the number of suspensions (drums), simultaneously processed in the zone of each transport robot up to 7; -number of bathrooms, serviced by a transport robot up to 31. Benefits and features: 1. the work of the multiprocessing lines without a hard rhythm. 2. the possibility of calculating minimum required system configuration. 3. programming management system is available; availability of correction in the course of work. 4. Reliability and noise immunity work lines due to:-the integration of command and control functions to a robot; -lack of cable connections in line; -sealing of all units of the system; -vitality robotic line, through the lock razladivšihsâ technological operation. 5. Subsequent models of robotic systems, while maintaining the principles of construction, enhanced features and control options.