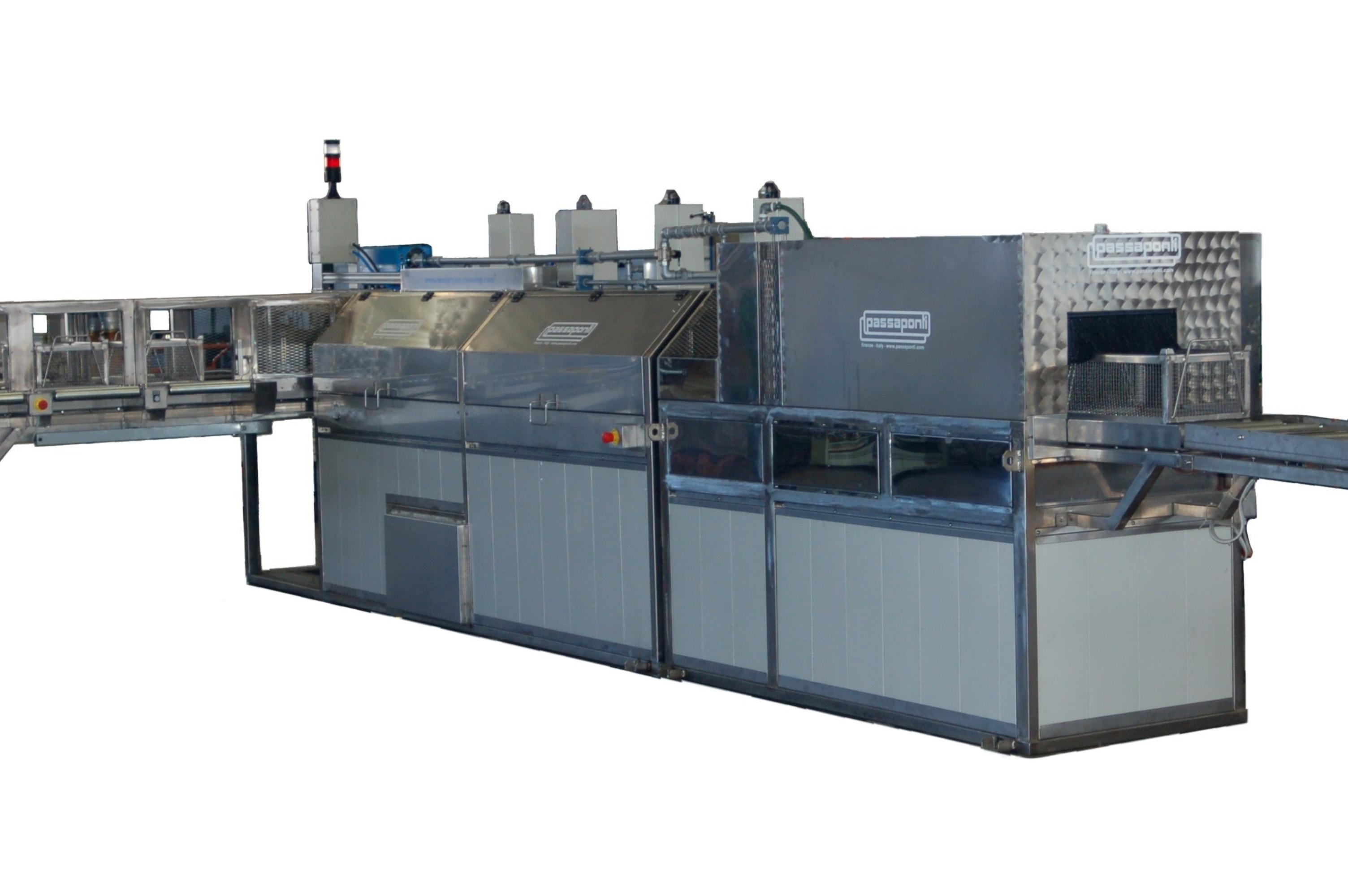

PASSAPONTI metal cleaning technology

S.r.l.

MULTI-DIP-stage high productivity machines

Industrial machines and equipment > Surface treatment > Washing machines: immersion, spray

Industrial machines and equipment > Surface treatment > Washing machines: immersion, spray

MULTI- DIP combines washing methods and technologies to achieve the highest levels of cleanliness. It is normally used for precision cleaning and treatment of components and high precision mechanical parts that require immersion or spray/dip combination with tight control of the process. Multi-automatic plants

DIP can combine different technologies such as immersion, ultrasonic and spray with virtually any process product, whether it is acid or alkaline. Using different cleaning methods and different operating principles, multi-stage automatic plants can meet the highest requirements for precision washes.

high standards of cleanliness and productivity are the peculiarities of the system. The absence of dead times, typical of other multi-stage systems, and maximum functional flexibility allow configurations and unattainable performance. For example, the most

long 46 metres long plant built with automated stages, 36 and as short as only 2.9 meters with three stages and a production of a basket every 70 seconds.

DIP can combine different technologies such as immersion, ultrasonic and spray with virtually any process product, whether it is acid or alkaline. Using different cleaning methods and different operating principles, multi-stage automatic plants can meet the highest requirements for precision washes.

high standards of cleanliness and productivity are the peculiarities of the system. The absence of dead times, typical of other multi-stage systems, and maximum functional flexibility allow configurations and unattainable performance. For example, the most

long 46 metres long plant built with automated stages, 36 and as short as only 2.9 meters with three stages and a production of a basket every 70 seconds.

multistage precision cleaning, surface treatment, non-destructive penetrating fluids

Lavaggio, decapaggio, passivazione, fosfatazione, alodizzazione,sgrassaggio, decarbonizzione,disossidazione,protezione,CND, Controlli non distruttivi, liquidi penetranti

* Indicates required field