PASSAPONTI metal cleaning technology

S.r.l.

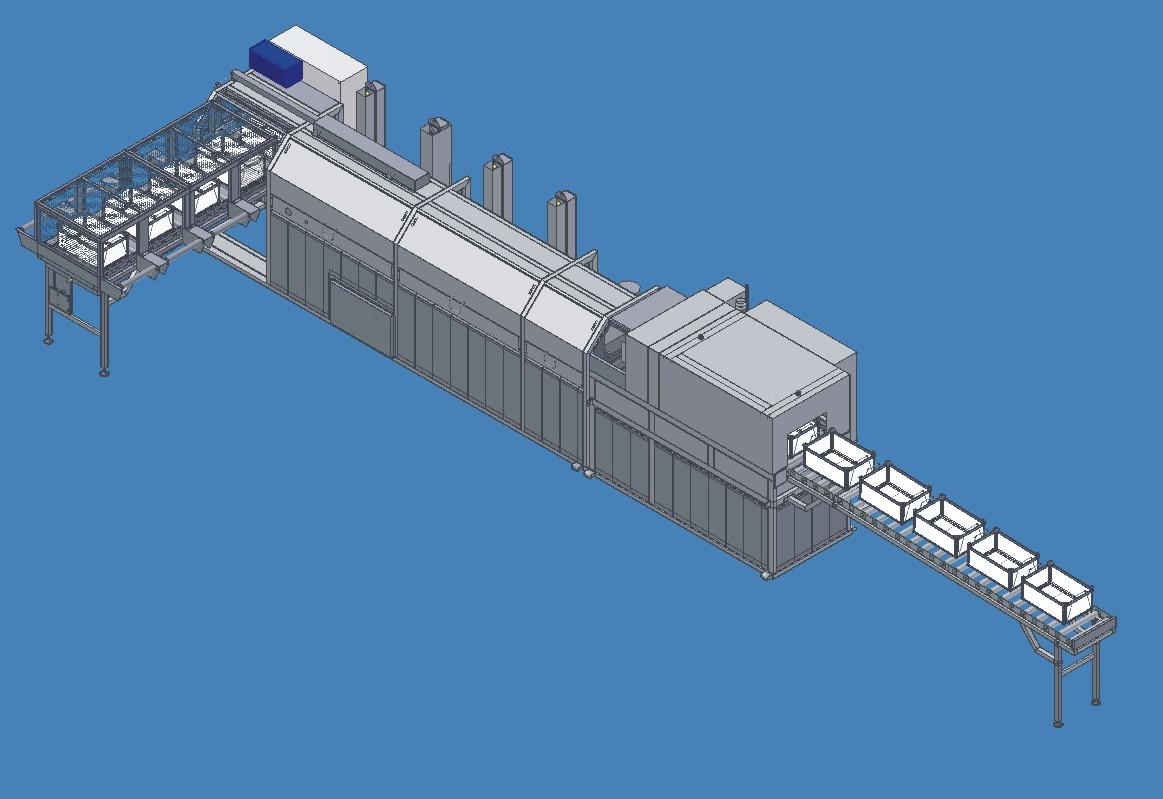

AGI-DIP immersion agitation washers

Industrial machines and equipment > Surface treatment > Washing machines: immersion, spray

Industrial machines and equipment > Surface treatment > Washing machines: immersion, spray

AGI-DIP ® simple answers to complex problems

AGI-DIP ® washers constitute the most rational solution for problems of immersion process is required when cleaning with agitation. Produced with or without heating, are employed both in production and MRO (Maintenance Repair overhaul) for degreasing, derusting, passivation, phosphating, decarbonisation, protection, stripping and more.

The

operating principle is based on a tank containing liquid and a pneumatic system for lifting, lowering and alternate vertical movement of the platform within the liquid. The system greatly reduces the washing time and increases its effectiveness without affecting the duration of liquid and without increasing evaporation.

AGI-DIP ® Ecomatic washers

automated MULTI- lines

operating principle is based on a tank containing liquid and a pneumatic system for lifting, lowering and alternate vertical movement of the platform within the liquid. The system greatly reduces the washing time and increases its effectiveness without affecting the duration of liquid and without increasing evaporation.

AGI-DIP washers can be configured for use with aqueous or hydrocarbons, classified type A1 of EN

12921.3 that do not generate vapors. by a machine to a system

starting from the basic configuration, AGI-DIP ® has evolved into a system with wide range of models, configurations, automatic lines, all have the same principle of operation, simple construction and high-performance

the system AGI-DIP ® is based on modularity to achieve Flexible modular systems with functional processes, even with drying, for all applications: from precision up to washing interprocess

MRO. represent the natural evolution of the basic models. Maintain the characteristics but are designed as compact modules with frontal loading for use online or as single units. All functions are automatic and the operator only needs to transfer the basket from one unit to another effortlessly.

The AGI-DIP ® Hyper represent the most advanced in the immersion cleaning with or without ultrasound. Exceeds the typical limits of immersion cleaning and enhances performance. The process is completely automatic, controlled by PLC.

DIP ® maximize flexibility and productivity of the system and the benefits speak for themselves: unlimited number of stages and production capacity of a basket every 70 seconds.

Treatment by immersion with agitation and/or with ultrasonic washing, rinsing, passivation, protection,

Immersione, agitazione, sgrassaggio, decarbonizzazione, disossidazione

* Indicates required field